Thickness measurement for industrial applications

for material thickness ranges from 1.5mm to 500mm,

for temperature ranges -50°C up to +650°C,

without couplant and without need to prepare the material surface

Industrial applications

Wall thickness measurement of metal pipes, vessels and sheets, which also can be very hot or cold, with a laminated or raw surface

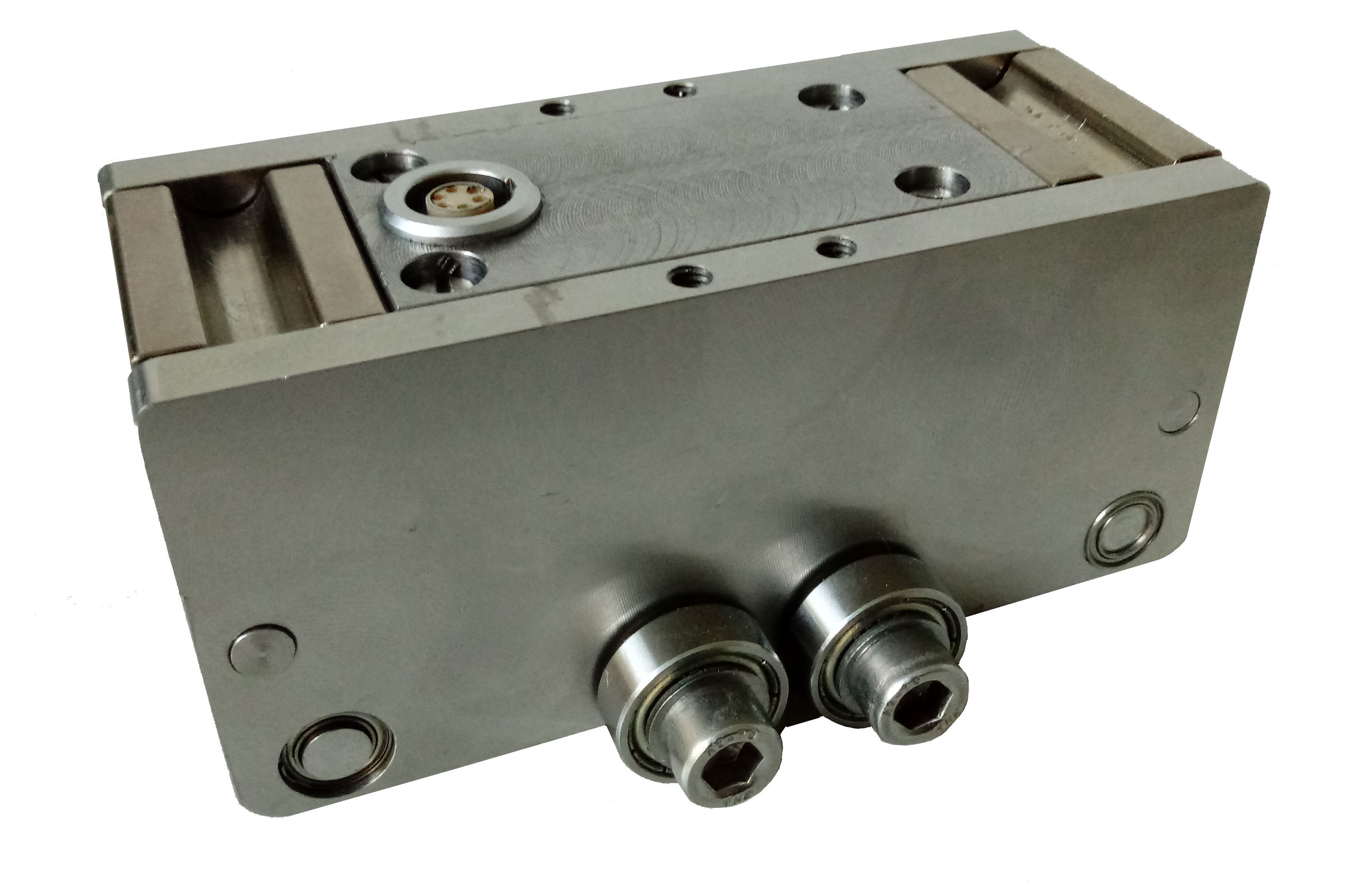

Suitable testing devices for wall thickness measurement by EMAT ultrasound technology

|

|

|

|

| |

|

Operating mode and features

EMAT ultrasound can determine the material thickness on electrically conductive material (steel, aluminum, copper, ...) without coupling. An exact angular position of the probe relative to the material surface is not necessary. The workpiece does not need to be moistened and dried again after inspection. EMAT inspections are possible at high or below zero temperatures. The surface may be raw, i.e. no efforts to clean or de-rust the material surface are necessary. Coatings can remain on the workpiece with a thickness up to 2.5 mm.

Thickness measurements with EMAT are possible for material thicknesses from 1.5mm to 500mm and can be used in a temperature range from -50 °C to 200 °C with continuous contact and up to 650 °C with special probes and short contact (approx. 5 seconds).

With an additional temperature probe, the temperature of the workpiece can be included in the measurement to improve the measuring accuracy.

A meter counter allows to record the distances during wall thickness measurements.

Exact thickness measurements are possible after instrument calibration. For this purpose, a calibration block with defined dimensions of the material is required. In the case of coarse-grained or strongly attenuating (soft) and / or very thick material, different calibration values may be necessary for optimum evaluation of the echo. Manual and menu guide supports you with calibration.

All device settings can be saved as a specific setup for an application for documentation and the exact repetition of a measurement.

A wide range of probes is available.

|

|

| EMAT sensor carriage for replaceable coils | EMAT probe |

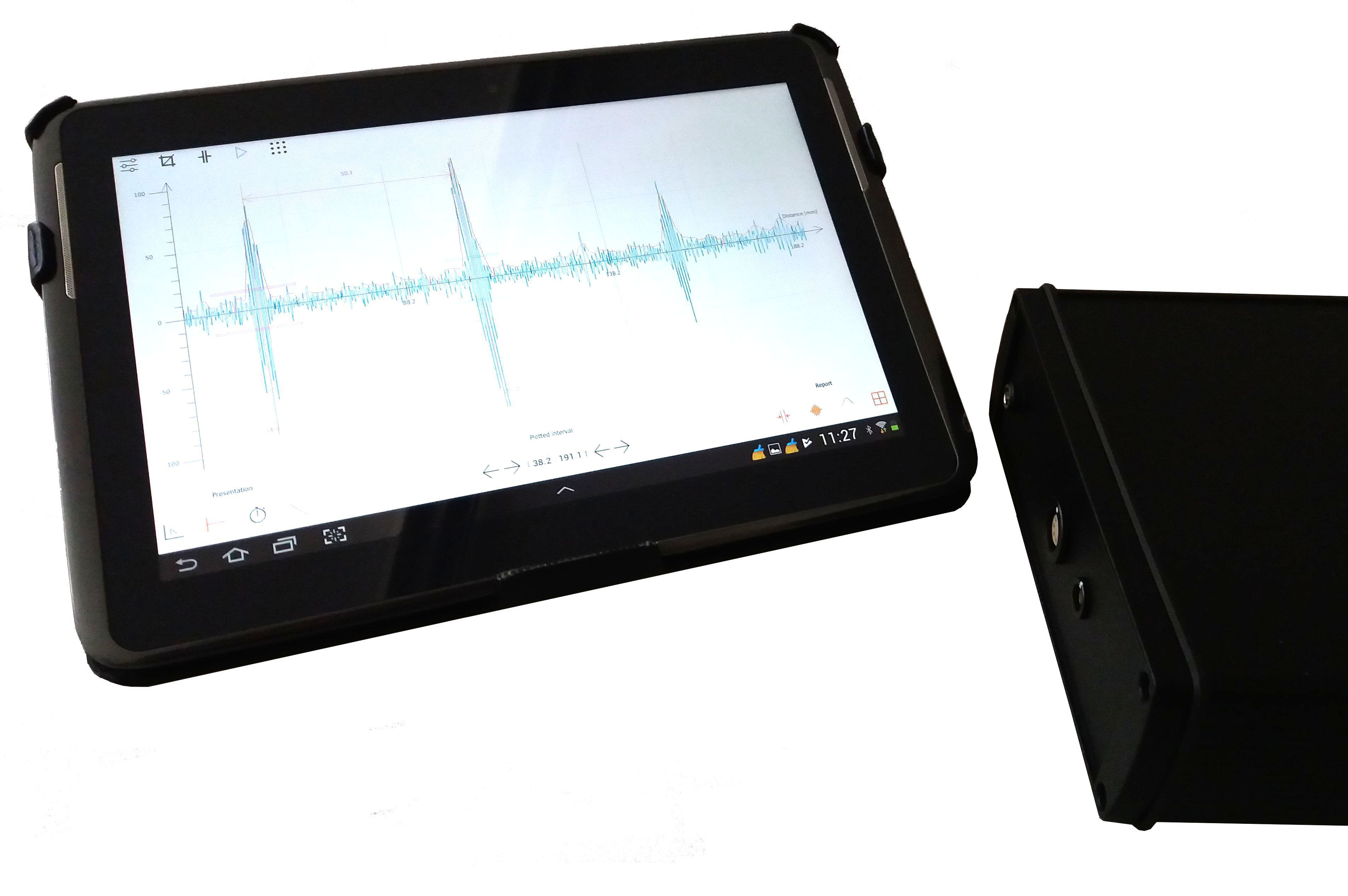

The meter can be remotely controlled via the Ethernet port and a software that can be installed on Windows computer. The data analysis can take place on the computer.

Results from thickness measurement:

- Direct value display in the device and the A-picture to see the details of the measurement (see the following figure)

- Alarm signals in the display of the device for exceeding and falling below the thresholds

- The alarm signals can be sent to external devices

- From each measuring point a report sheet with all parameters and the A-picture can be stored on the hard disk of the devicedirekte Wertanzeige im Gerät und das A-Bild, um die Details der Messung zu sehen (siehe nachfolgendes Bild)