Corrosion inspection for pipes, tanks, sheets, ...

Detect corrosion with EMAT ultrasound technology,

fast and reliable, without couplant, without prior surface treatment

Industrial applications

Detect corrosion at pipes, vessels, plates, ... - e.g. in refineries

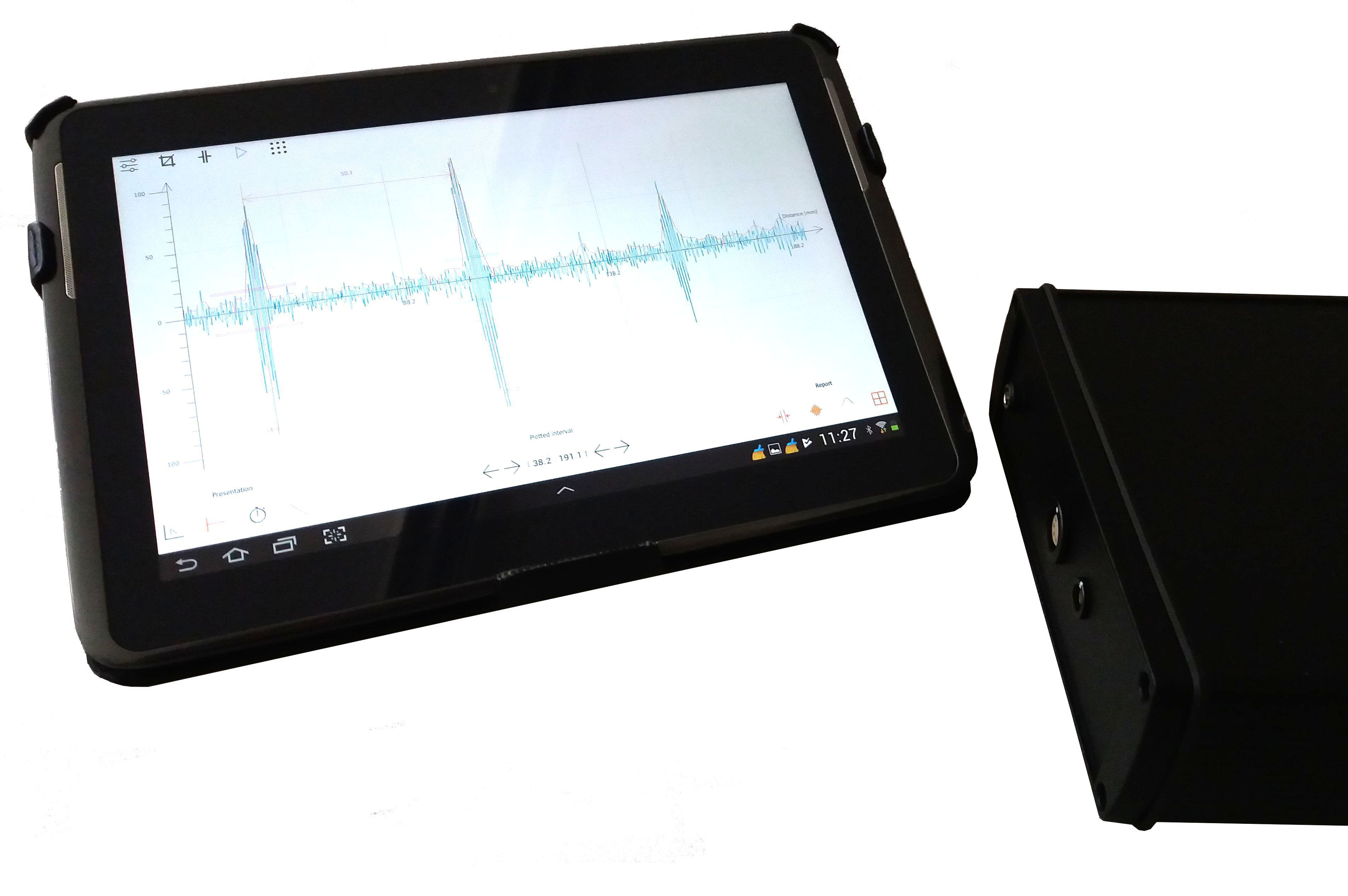

Suitable testing devices for corrosion inspection with EMAT ultrasound technology

|

|

|

|

| |

|

Operation mode and features

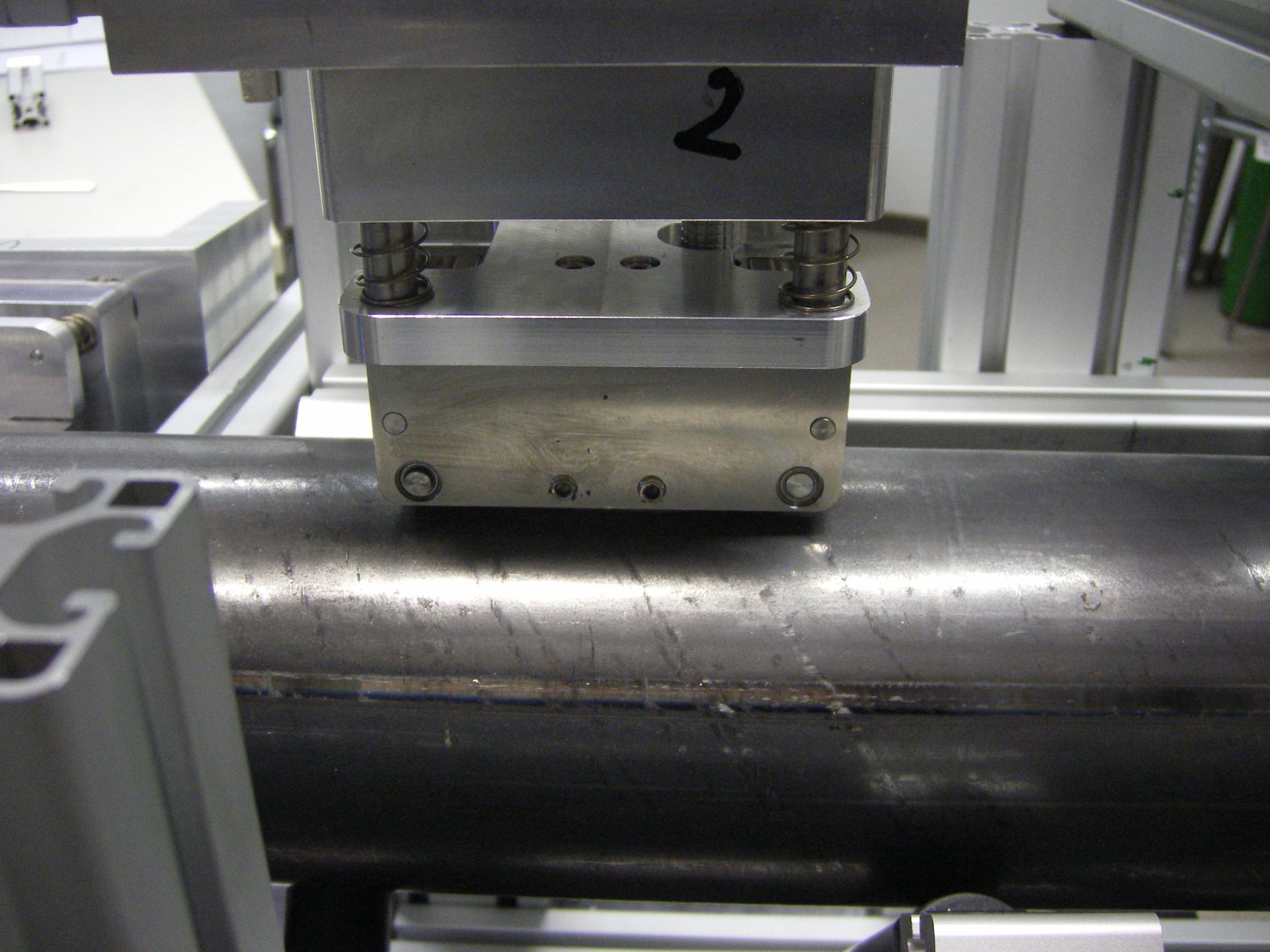

EMAT ultrasound can determine the material thickness on electrically conductive material (steel, aluminum, copper, ...) without coupling. An exact angular position of the probe relative to the material surface is not necessary. The workpiece does not need to be moistened and dried again after inspection. EMAT inspections are possible at high or below zero temperatures.

The surface may be raw, i.e. no efforts to clean or de-rust the material surface are necessary.Coatings can remain on the workpiece with a thickness up to 2.5 mm.

The measuring range is 0.1 to 5m from the probe into the material, with frequencies from 100 kHz to 1 MHz.

EMAT realizes a quick pass over the pipe in order to determine the flaws qualitatively. If a quantitative examination (size of the defects) is required, then piezo ultrasound equipment is necessary.

|

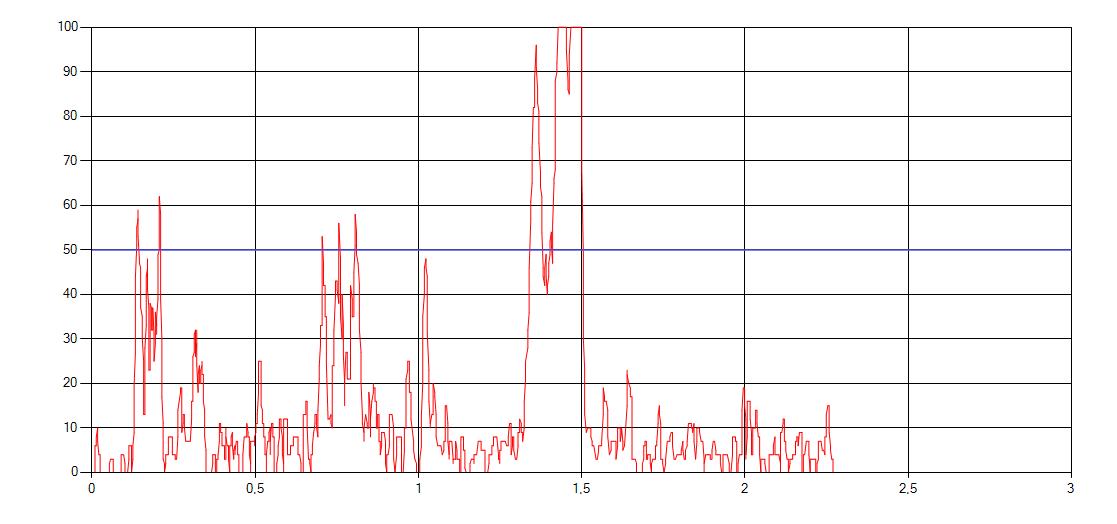

The following photo shows the diagram of a corrosion inspection of an approx. 2.3m pipe piece. The pipe was tested from the outside to detect corrosion in the interior. The approx. 30cm long exceedance of the threshold as well as two peaks indicate corrosion.