Surface inspection for materials also in hot conditions

EMAT detects also small holes in the material surface,

also in areas which are not accessible directly

Industrial applications

Inspection of rolled, drawn and cold or hot-formed parts where the quality of the surface is important

Suitable testing devices for surface inspection with EMAT ultrasound technology

|

|

|

|

| |

Operation mode and features

EMAT ultrasound can determine the material thickness on electrically conductive material (steel, aluminum, copper, ...) without couplant. The workpiece does not need to be moistened and dried again after inspection. EMAT inspections are possible at high or below zero temperatures.

EMAT surface waves are very sensitive to surface defects. The waves can follow a curved surface, i.e. it is also possible to test pipes and rods starting from a point or along a line.

Defects are found in the range of 1/10 of the wavelength and at a distance of 10 to 1,500mm from the probe.

The depth of penetration into the material is dependent on the test frequency and is half the wavelength (0.5mm to max. 12mm), whereby with high frequency and lower penetration depth smaller events can be detected than with low frequencies. The propagation direction of the sound waves in the material is always parallel to the entrance wall.

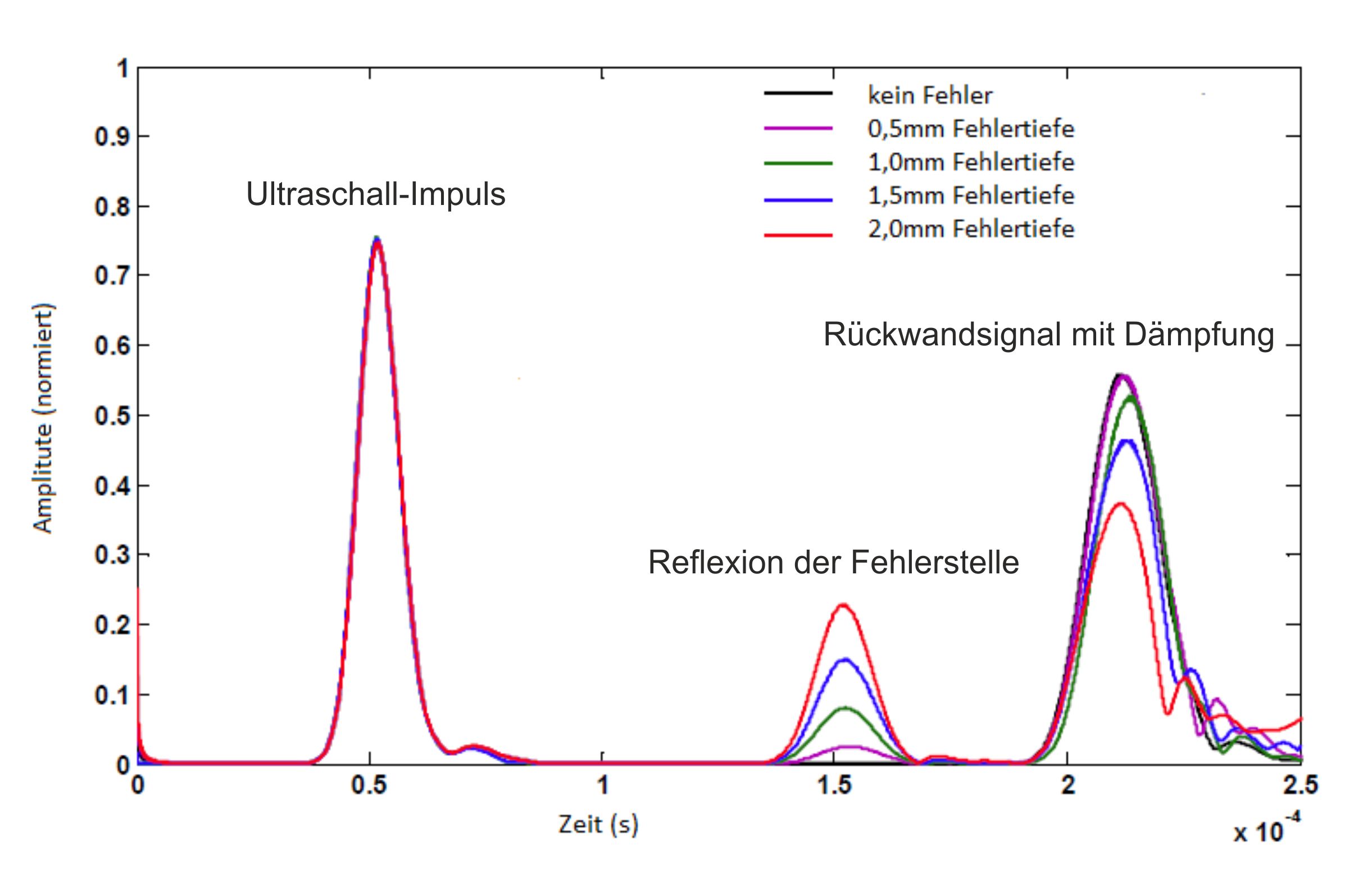

Folowing pictures shows the principle how to evaluate echo signals:

Depending on the flaw size, different strong reflections from the flaw itself and / or the attenuation of the back-up signal can be used for evaluation and thus positioning of the gate.

Test results are A-images, line diagrams (also location of flow when used with rotary encoder) and B-pictures as another visualization form the position, length and strength of the errors.