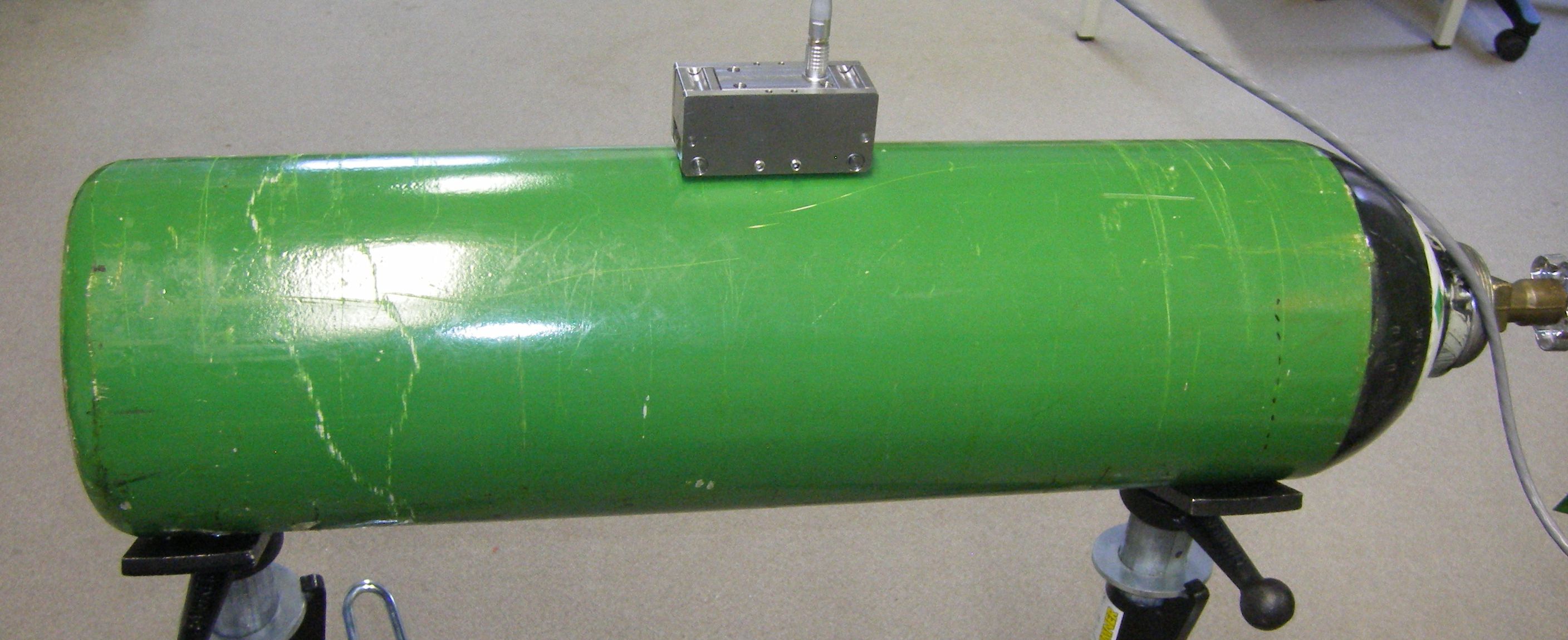

Crack detection, e.g. for pressure cylinders or gas accumulators in wind engines

Inspect vessels, pressure cylinders, gas accumulators, ... to detect cracks,

without dismantling, without prior surface treatment

Industrial applications

Pressure cylinders, vessels, gas accumulators, pipes and other workpieces to detect cracks

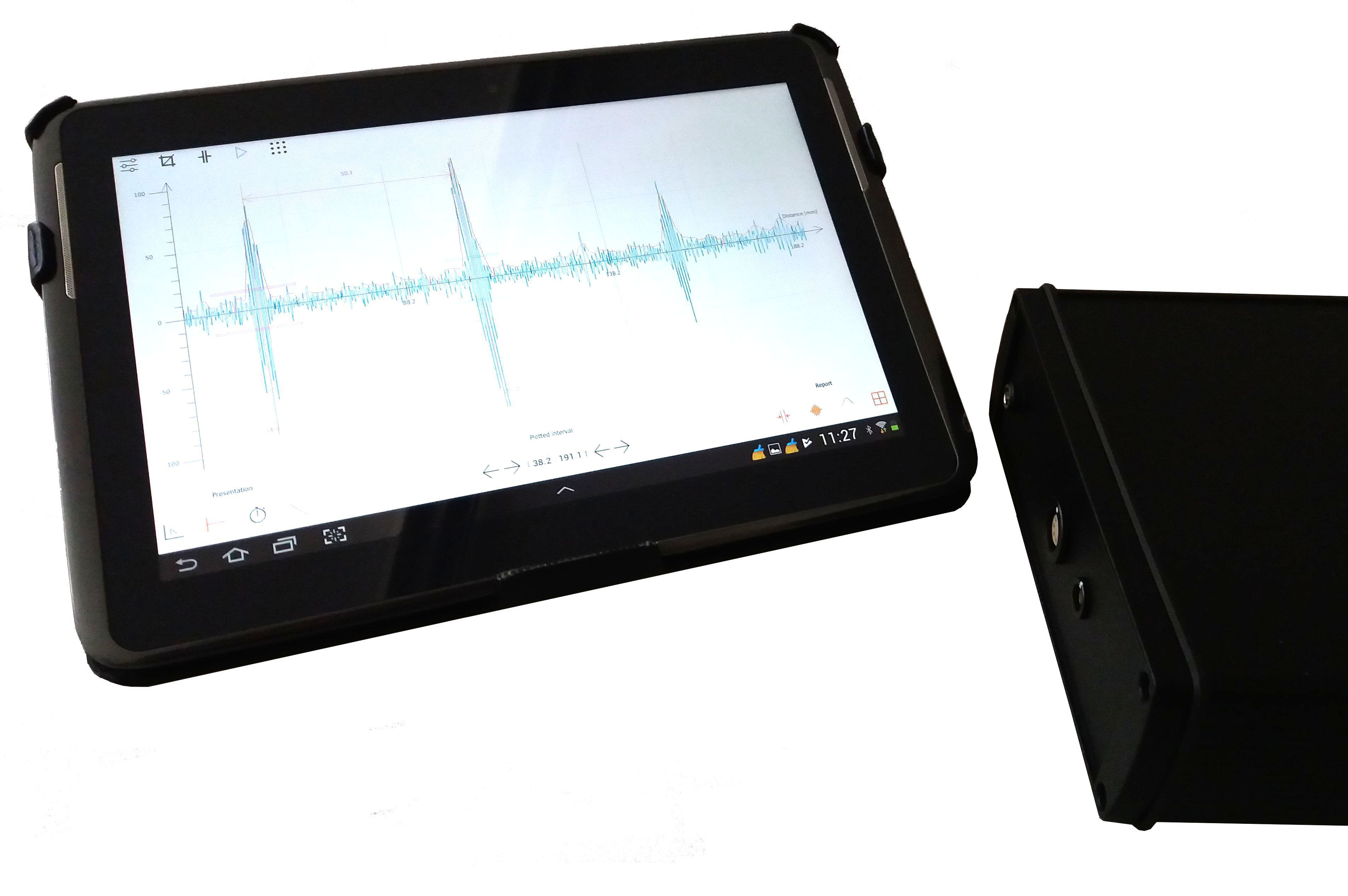

Suitable testing devices for crack detection with EMAT ultrasound technology

|

|

|

|

| |

Operation mode and features

EMAT ultrasound can detect flaws in workpieces made from electrically conductive material (steel, aluminum, copper, ...) without couplant. An exact angular positioning of the probe relative to the material surface is not necessary. The workpiece needn't to be moistened and dried after inspection. EMAT inspections are possible at high or below zero temperatures.

The surface may be raw, i.e. no efforts to clean or de-rust the material surface are necessary. Coatings can remain on the workpiece with a thickness up to 2.5 mm.

A range of 0.3mm - 9mm wall thickness can be tested. Thicker materials may mean a performance decrease depending on the material (recognizable defects).

By application of mobile EMAT testing devices, pressure cylinders or gas accumulators can be inspected without dismantling (e.g. in wind engines) and even without surface treatment.

Material inspections can be recorded. So it's possible to compare new results with those of a previous tests to recognize and evaluate changes.

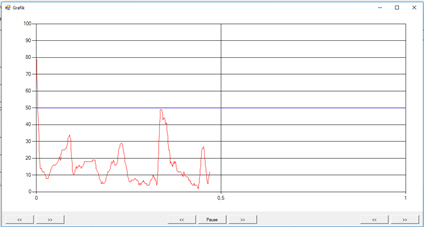

Inspection of a vessel with a long of 0.5m without flaws but just below the threshold.

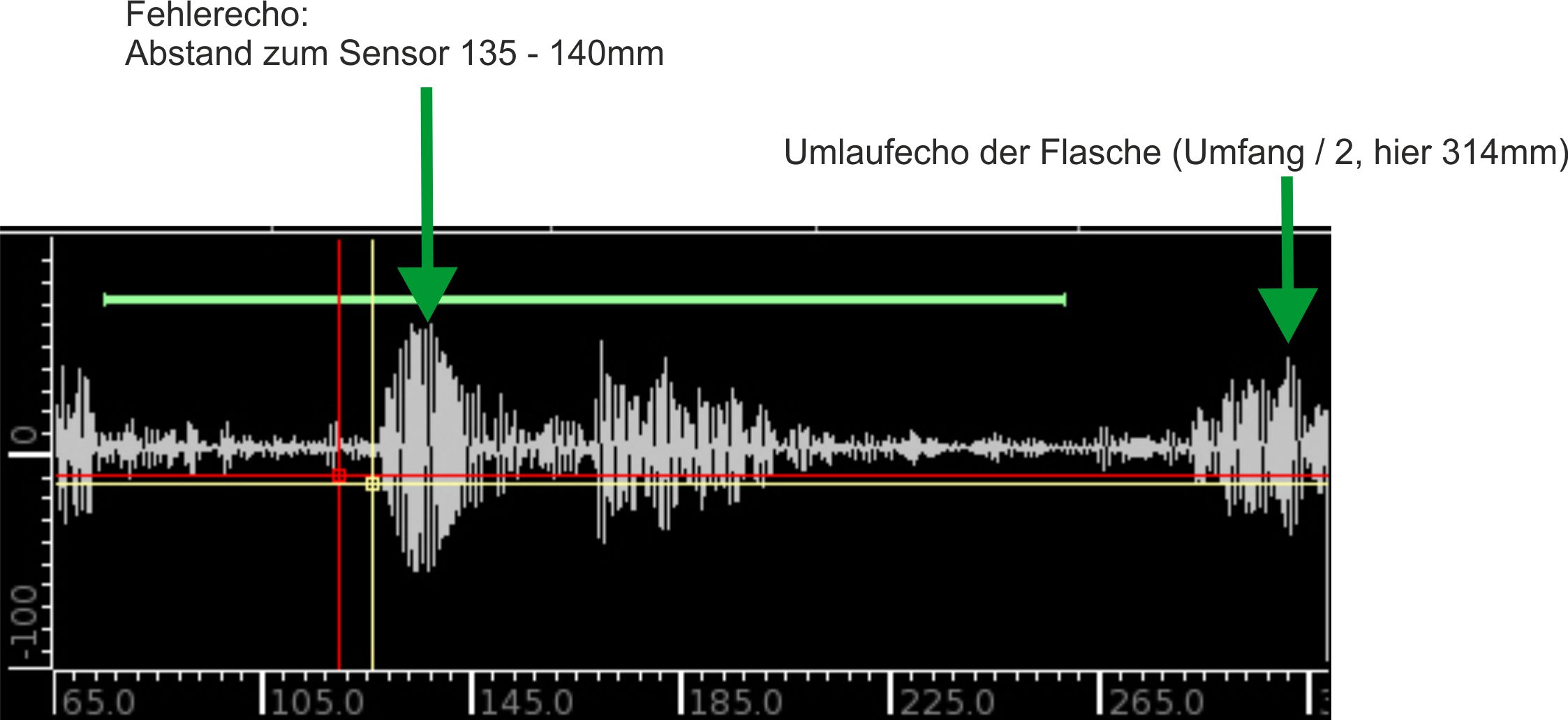

Following picture shows the A-Scan with the distance from the defect to the probe that can be read on the X-axis.