Weld inspection between thin sheets - Tailor Welded Blanks

Inspection of welding seams between thin sheets ,

also between sheets of different thickness

Industrial applications

Inspection of welded thin sheets, e.g. in the automobile industry (Taylor Welded Blanks), mobile or integrated in the production process

Suitable testing devices for the weld inspection of thin sheets with EMAT ultrasound technology

|

|

|

|

| |

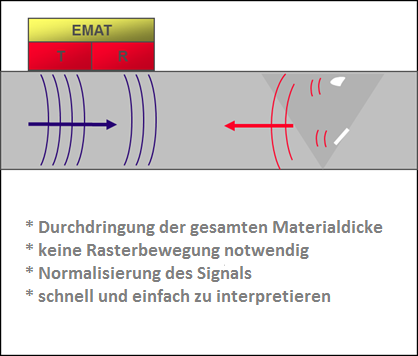

Operation mode and features

EMAT ultrasound can detect flaws in workpieces made from electrically conductive material (steel, aluminum, copper, ...) without couplant. An exact angular positioning of the probe relative to the material surface is not necessary. The sheet needn't to be moistened and dried after inspection.

With guided waves, the entire volume of the sheet is filled and checked for defects accordingly.Mit geführten Wellen wird das ganze Volumen des Bleches gefüllt und so auf Fehler geprüft.

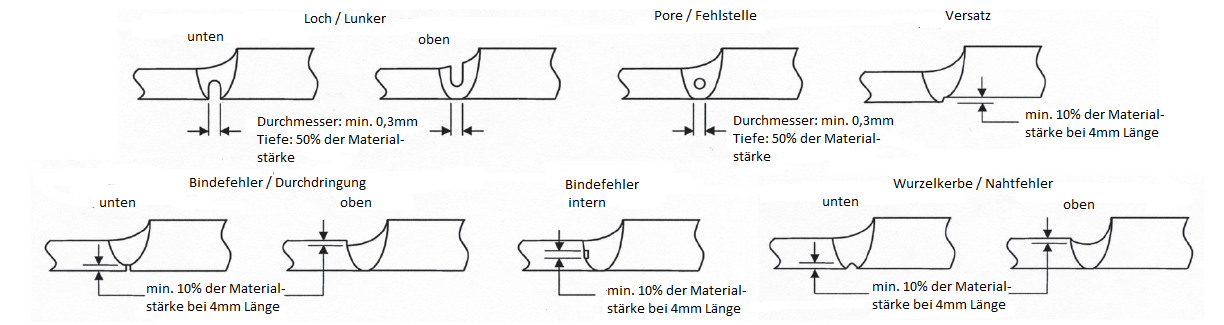

EMAT detects holes and cavities from a size of 0.3mm:

In addition to standard coils, focussed double coils (planar channel, point channel) can be used with the probe to better detect small, spot-shaped defects.

The welding seam, whether straight or curved, is at first inspected with the activated planar channel and then by point channel parallel to the welding seam. When using a rotary encoder, to also record the position of the defects in the line diagram up to 10m in length (in mobile use).